1. Context & Problem

- US Foods is one of the largest distributors of produce nationwide servicing restaurants and large institutions.

- Traditionally, customers received scheduled shipments of items in bulk while purchasing special, limited quality, items through third parties such as Restaurant Depot.

- Purchasing from different vendors costs both administrative paperwork and time for customers.

- Therefore US Foods introduced a new service allowing shipmen of special items in low quantities on-demand.

- We were tasked to introduce this on-demand service while also optimizing the overall ordering experience.

2. What We Did

- Collected feedback regarding current experience.

- Redesign ordering, checkout and tracking interfaces.

3. Key Findings

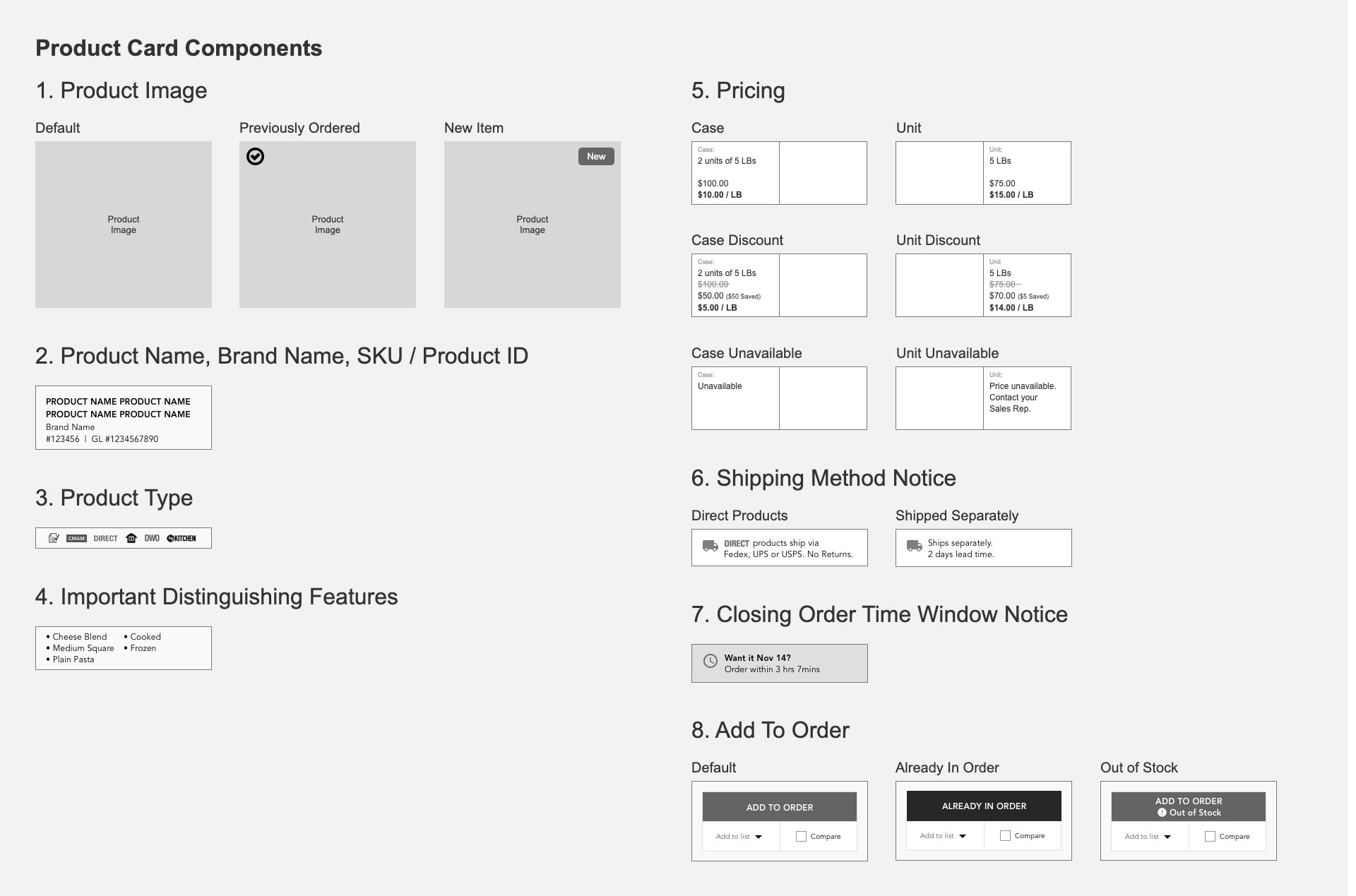

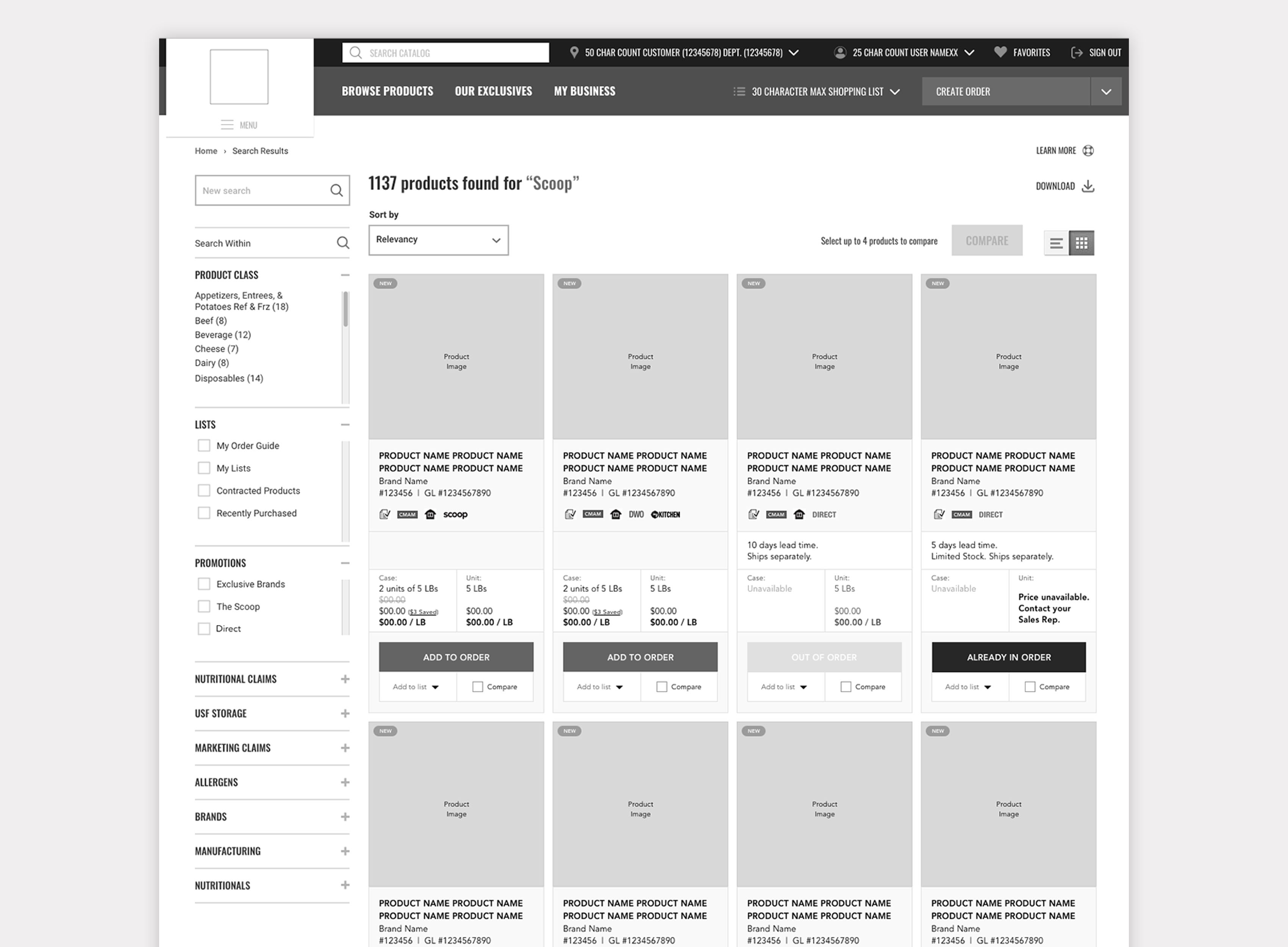

- Lack of consistency in product cards evolved throughout the years resulting in a cluttered interface.

- Scanning product listings behavior is similar to B2C, accurate images provide fastest recognition while product and brand name are used for confirmation.

- Need for on-demand specialty items, in custom amounts, and shipped separately from usual distributor truck.

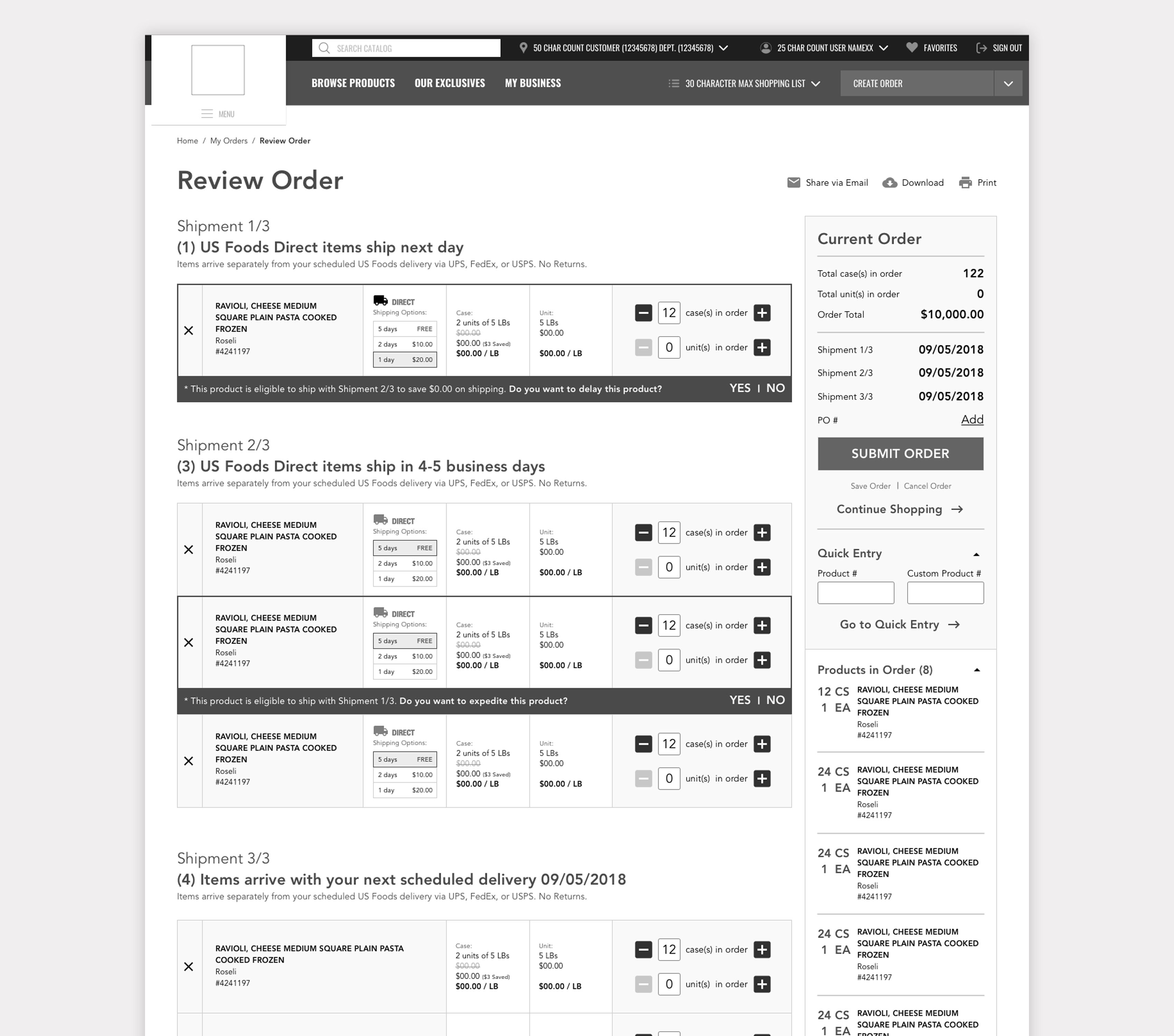

- Order review screen lacks hierarchy, resulting in difficulty understanding what will be received when.

- Customers need more accurate and transparent tracking information to plan their day. Common B2C tracking leaves too many hours for guessing arrival of shipment.

4. Brainstorming

Products are either produce delivered by truck or courier, or large kitchen equipment.

- Map all product variations and delivery options to cover all escenarios.

- Create product cards presenting crucial information in an non-overwhelming manner.

- Respect well established ecommerce shopping behavior.

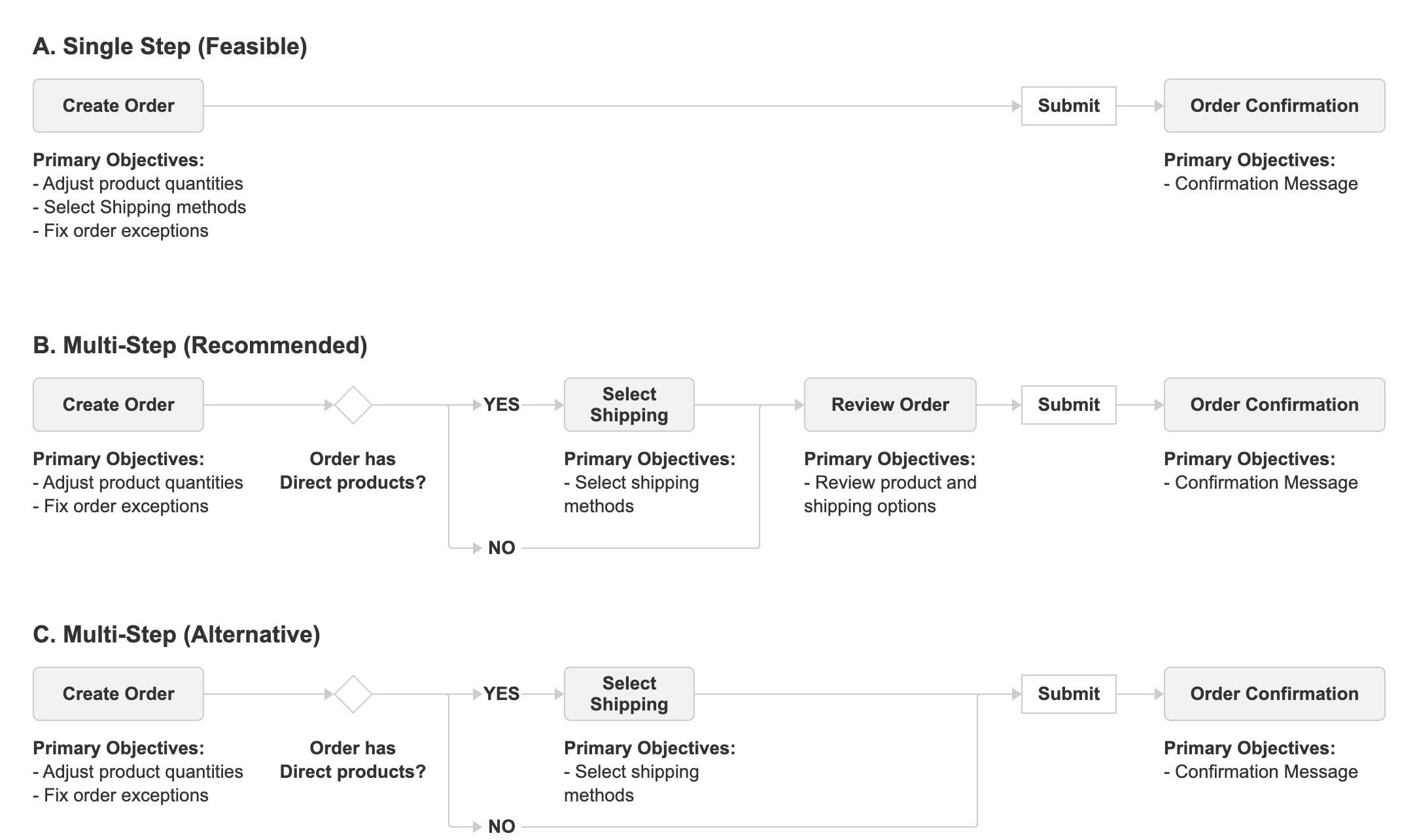

A single order contains products shipped on different dates by private truck or courier. Options are selected before checkout.

- An order can have multiple shipment dates and methods.

- Shipments are tracked individually regardless of order.

- Track shipments for each day.

5. Recommendations

Product cards with consistent components for specific information customers look for.

- Adaptable to both card and list layouts.

- Surface important features to differentiate similar products.

- Ability to compose the entire order from the listing page.

Order split by shipment groups for restaurants to plan around availability of ingredients.

- Reviewing order is also the main screen to finish composing item quantities.

- Group items shipped by courier vs private trucks.

- Group courier items by shipping date.

Make use of tracking shipment information for customers to know exactly when to expect delivery.

- Visualization of private truck in-route.

- Courier tracking integration to avoid checking on courier website.

- Update notifications for issues such as unforeseen delays, broken items or missing stock.

6. Challenges & Learnings

Getting acquainted and learning the multiple current and legacy products, pricing models and product characteristics proved to be the major obstacle. Little documentation of system specifications and rules were provided, resulting in discovering new information in every meeting. System behavior mainly existed in stakeholder knowledge.

To solve this issue, we created multiple interim documents documenting specifications and functional behavior. A running list of questions was updated every time clarification was needed. None of these documents were meant for the client but have taken much of the team’s effort to maintain and kept us coordinated throughout the project.

7. Reference Material

For a deep dive into the project, please reference the following links: